Technical advantages of 3C-SiC for preparation of MOSFET.

Ⅰ International research has proven that 600-1200V MOS devices are feasible

Ⅱ High channel mobility 300cm2/V.s

Ⅲ The typical value of 4H-SiC is 10-100 cm2/V.s

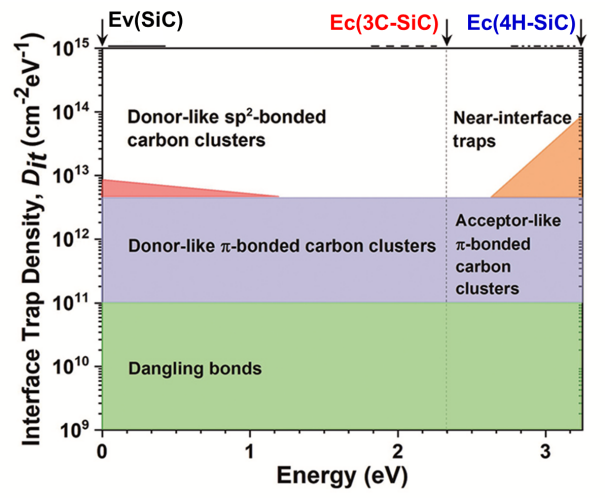

Ⅳ Low interface state density,significantly improves device reliability

Ⅴ Low on-resistance

Ⅵ Ohmic electrode process

|

Items |

Standard |

|

|

Poly-type |

4H-p、3C-n |

|

|

Surface |

(0001) Si-face |

|

|

Off-orientation |

4deg-off [11-20] |

|

|

Conductivity |

n-type / p-type |

|

|

Dopant |

Nitrogen / Aluminum |

|

|

Carrier Concentration |

Range |

1E15 ~ 5E16 cm-3 |

|

Tolerance |

±15% |

|

|

Uniformity(s/mean) |

≤10% |

|

|

Epi thickness |

Range |

5 ~ 100 μm |

|

Tolerance |

±10% |

|

|

Uniformity(s/mean) |

≤4% |

|

|

Surface roughness |

≤ 2 nm |

|

Notes:

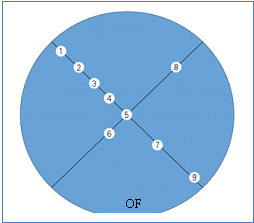

Measure points for Thickness and Carrier Concentration . Generally, the test method concludes 9 points (as shown in the figure), also the customer can assign the test method.

Ⅰ Carrier Concentration by Hg-CV.

Ⅱ Thickness by FTIR.

Ⅲ The roughness is tested by AFM,the scan size is 10×10μm2.

Ⅳ Better products can be customized.

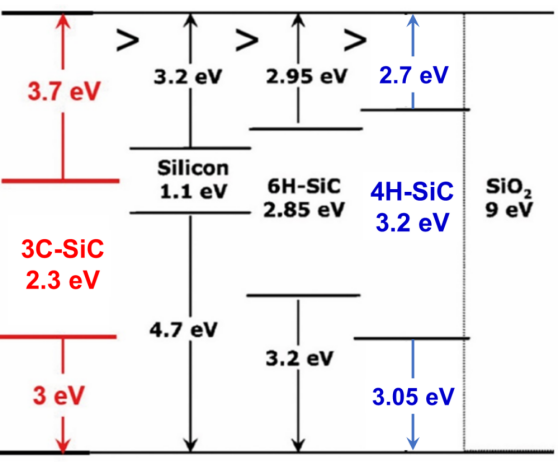

3C-SiC interface state capture center entering conduction band, and the density of gate oxygen interface states formed by the interface state is significantly lower than that of 4H-SiC

The conduction band energy level difference of 3C-SiC/SiO2 is significantly higher than that of 4H-SiC/SiO2. That is beneficial for improving the reliability of gate oxygen